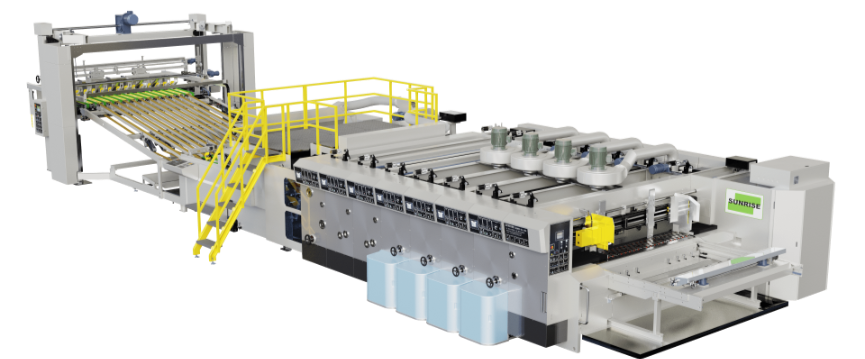

S-925 Series

Powering Your Solutions

S-925 Series

Classic Mainstream

APPLICATIONS

Operating System

- Production Management Software

- Remote Management System

- Ordering Set-up Function

- Intelligent Graphical User Interface

- Real-Time Information Dashboard

- Optimized Quality Management

- Downtime Information Processing

- Customized Functional Reports

-

Computer Interface Control System

Centralized control system, ensuring synchronized operation and status updates for each unit. -

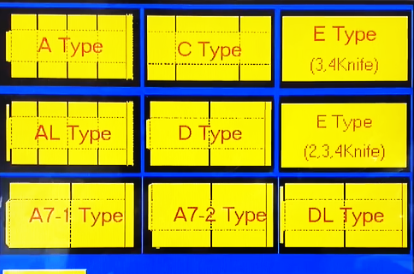

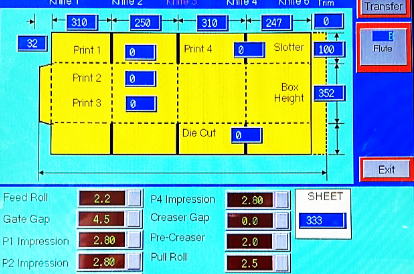

Intelligent Graphical User Interface

Operator can efficiently access information and navigate seamlessly, with the flexibility to switch between various box-type production modules.

-

Ordering Set-Up Function

Adopting simple graphical user interface, the system automatically interprets the relevant functional parameters of each unit, eliminating the necessity for manual repetitive adjustments.

Feeder Unit

- Sun Automation feeding system, capable of adapting to various conditions of corrugated sheet.

- Sunrise's vacuum system enhances the flexibility tolerance of corrugated sheets, minimizing feeding challenges resulting from variations in inconsistent cardboard quality, such as titling or shifting issues.

-

Suitable for cardboard sheets with a thickness range of 1.5~9mm (AB-E flute), it accommodates to a variety of production requirements, including different thicknesses of cardboard sheets feeding.

-

Connect to the computer system for preconfiguring corrugated sheet types and dimensions, allowing for automatic adjustments in sheet feeding distance, gap between feed rolls and stopper positions.

-

Maximize stroke extensions automatically adjusted feeding mechanism to minimize damage to the cardboard sheets.

-

工-Beam Steel Structure

Minimize operational vibrations.

Ensure stability throughout the feeding process.

Improve the precision of the feeding mechanism.

-

Lead Edge Feeding with Adjustable Vacuum System

Sun Automation lead edge feeding system, in conjunction with Sunrise's designed vacuum system, enhances adaptability to varying qualities of cardboard sheets.

-

Detachable Feeder Cylinder

Detachable feeder cylinder, streamlineling the replacement and maintenance process.

Printer Unit

-

The “RETURN” function with automatic restoration for precise print positioning, enhances machine efficiency and significantly reduces waste production.

- The vacuum transfer device minimizes displacement of print dots, allowing for adjustable gaps between the cardboard sheet and printing plate to achieve the state of “kiss-touch.” This ensures high print quality for both print dots and full-page printing.

- Doctor blade chamber inking device delivers a consistent ink volume during both high and low-speed rotations, guaranteeing clarity in print dots, fine text and even full-page printing.

-

Doctor blade chamber inking device offers easy maintenance, minimal ink consumption, short cleaning time and high system stability.

- Pneumatically controlled anilox ink transferring timming

- Automatic printing plate locking device

- Automatic ink shortage detection system

- Protective device with entry detection

-

Doctor Blade Chamber Ink Distributing System (Optional)

A doctor blade chamber inking system ensures stable print quality and ink consistency in high and low-speed operations. The optional quick-change blade system enables blade replacement in under one minute. -

Automatic Ink Shortage Detection System

To protect the anilox roll from damage caused by insufficient ink, the system will activate an alarm notification upon detecting an ink shortage. -

One Press "RETURN" Feature

Following a required pause or shutdown, simply press “RETURN” to resume production without the need for additional adjustments.

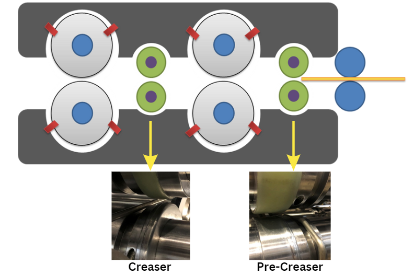

Slotter Unit

- The dual-shaft slotting mechanism with independent knife shafts enables unrestricted box height, prevents collisions, and simplifies slotting depth adjustment without the need for the tool dissassembly, effectively saving operational time.

- The linkage plate, in collaboration with linear guides and a ball screw, enhances the efficiency and precision of controlling the slotting and creasing operations for corrugated sheets.

- The slotting knife's fixed feeding gap eliminates adjustments for cardboard thickness, enhancing operational efficiency.

- Upon entering cardboard box dimensions needed, the machine automatically interprets slotting knife movement positions, simplifying operations and meeting production requirements.

-

Double-Shaft Slotting Mechanism

The dual-shaft slotting mechanism with independent knife shafts enables unrestricted box height, prevents collisions, and simplifies slotting depth adjustment without the need for the tool dissassembly, effectively saving operational time.

-

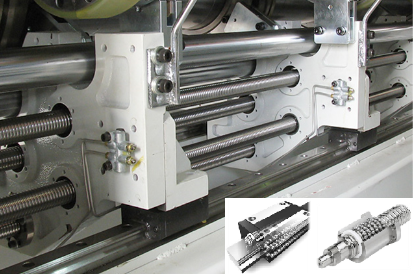

Lateral Movement Mechanism of Slotting Knives and Creasing Wheels

The moveable plate, in collaboration with linear guides and a ball screw, enhances the efficiency and precision of controlling the slotting and creasing operations for corrugated sheets.

-

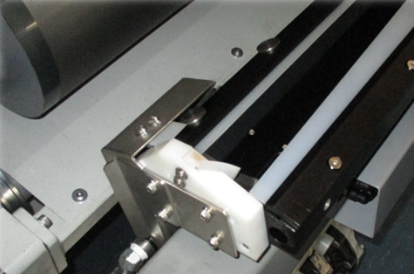

Glue Tab Cutting Device

The glue tab cutter holder is equipped with a cushion mechanism, extending the lifespan of the cutter and reducing the need for adjustments.

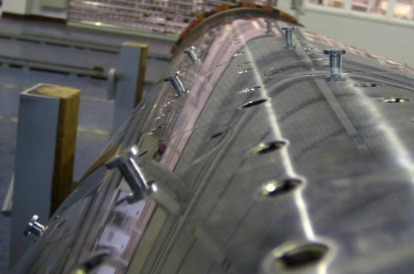

Die-Cutter Unit

- A 7-stage speed compensation system ensures precise synchronization of linear speeds between the anvil and the die-cutting cylinder.

- The quick-lock functionality of the die-cut mold (optional) enhances efficiency and decreases the time required for mold replacement.

- The electric anvil oscillation device evenly distributes the wear on the anvil surface, thereby extending the lifespan of the anvil roll.

-

Electric Anvil Oscillation Device

The electric anvil oscillation device evenly distributes the wear on the anvil surface, thereby extending the lifespan of the anvil roll. -

Anvil Grinding System

Restore the surface of the anvil roll to a smooth and good condition, improving operational stability. -

Quick-lock Die-Cut Mold Device (Optional)

The quick-lock feature of the die-cutting mold eliminates the necessity for screw tightening, enhancing efficiency, and reducing downtime during mold replacement.

LAYOUT

|

Models F Fixed / S Open Closed |

F-618 Series (27.5") |

F/S-925 Series (37.5") |

S-1227 Series(50") |

S-1628 Series (66") |

S-1633 Series (66") |

F-1227 High Productivity (50") |

|

Production Speed (minute / hour) |

350 / 21,000 | 320 / 19,200 |

250 / 15,000 |

150 / 9,000 | 150 / 9,000 | 300 / 18,000 |

|

Max. Cardboard Size (Continuous Feed) |

600 x 1800 | 860 x 2500 |

1150 x 2700 |

1520 x 2800 | 1520 x 3300 | 1100 x 2700 |

|

Max. Cardboard Size (Skip Feed) |

N/A | 1200 x 2500 |

1600 x 2700 |

2000 x 2800 | 2000 x 2800 | 1250 x 2700 |

| Min. Cardobard Size | 200 x 455 | 270 x 750 |

340 x 750 |

450 x 750 | 450 x 750 | 340 x 750 |

| Max. Print Area | 600 x 1700 | 870 x 2400 |

1170 x 2600 |

1560 x 2700 | 1560 x 3200 | 1170 x 2600 |

| Repeat Print Area | 700 | 953 |

1272 |

1676 | 1676 | 1272 |

| Cardboard Thihckness | 1.5 ~ 9 | 1.5 ~ 9 |

1.5 ~ 9 |

1.5 ~ 9 | 1.5 ~ 9 | 1.5 ~ 9 |

| Max. Width of Glue Tab | 45 | 45 |

45 |

45 | 45 | 45 |

| Max. Die-Cutting Area | 600 x 1400 | 900 x 2300 |

1200 x 2600 |

1600 x 2700 | 1600 x 3200 | 1200 x 2600 |

|

TV Top Print BV Bottom Print |

TV | TV |

TV / BV |

BV | TV / BV | TV |